Custom Test Equipment

Acquire data, test your controller with HIL, deploy an actuator test cell... or all three at once with a custom test system.

You Could Invent a Wheel Tester (without reinventing the wheel).

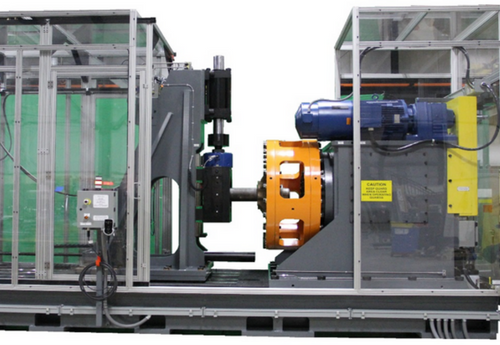

Test cells can take all sorts of forms. For GKN that meant deploying the world's largest wheel hub tester (capable of 80 ft-TONS of bending moment). Thankfully Genuen didn't have to start from scratch. We can't wait to see what you think of next.

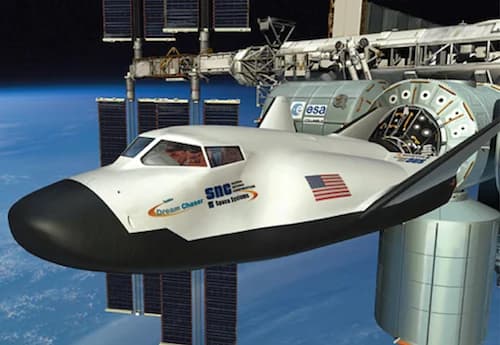

What's your mission?

While it's impossible to individually highlight over 1000 test machines, here are a few examples.

Test Systems Customized to Your Product

Genuen designs and builds custom test equipment to empower you with insight about your product. Here's a photo gallery for more examples.

SOFTWARE

Real-Time Control Software for Test Cells

Continuously developed for nearly 20 years, INERTIA is automation software we have developed for powering our real-time test cell designs to enable engineers to quickly configure their plant, develop test sequences, and operate the cell from a no-code, drag-and-drop interface.