In a move toward more electric aircraft (MEA) for a variety of reasons beyond reducing the carbon footprint of air travel, aircraft manufacturers are increasingly selecting electric components over their hydraulic and pneumatic counterparts. The Boeing 787 commercial airliner has led the way with a more efficient electrical system that uses less pneumatic power. One component that is a logical choice for electrification is an actuator. Aircraft manufacturers have been using electromechanical actuators for secondary flight controls for years; there is now an emerging trend of using electromechanical actuators for primary flight control surfaces.

While there are multiple kinds of electric actuators, electromechanical actuators have the potential to make the greatest environmental impact. Without the necessity of a hydraulic supply or engine air compressor and the various associated plumbing and ducting, electromechanical actuator systems weigh less than hydraulic (including electrohydraulic) and pneumatic actuators. This helps to reduce the overall weight of the aircraft, improving the fuel efficiency by requiring less fuel, which decreases carbon emissions. Electromechanical actuators also improve overall efficiency of the aircraft by reusing electrical power generated by the engine. Beyond the environmental impact, switching to less complex electromechanical actuators reduces maintenance costs. In addition, they provide improved reliability through greater accuracy and control, and improved quality through integrated diagnostic systems.

Electromechanical actuators are made of two elements that must be tested: the mechanical element, which must undergo physical testing, and the controller, which must simulate various loads through hardware-in-the-loop (HIL) model simulation.

In this blog post, we’ll be looking at some of the most critical considerations for testing electromechanical actuators and how system integration lab testing, which integrates both physical testing and HIL simulation, can accelerate the electrification of aerospace. As an expert in both physical test and HIL, Genuen can provide you with a tester that allows you to perform physical testing, HIL simulation, and integrated testing of electric actuators. This test system can be incorporated in your system integration lab (SIL) for verification with other critical components in your aircraft.

Electromechanical actuators consist of six major components that must be tested:

-

Electronic Control Unit (ECU) (which may or may not be integrated in the physical unit)

-

Motor

-

Power Transmission

-

Sensors

-

Manual Overdrive

-

Overspeed Break

The motor, power transmission, and manual overdrive must undergo physical testing, while the ECU and sensors can be simulated with a HIL system.

Physical Testing of Electromechanical Actuators

When preparing for physical testing of electromechanical actuators, there are several questions you need to answer to ensure your test solution is suitable. In what environment will this actuator operate? What is the duty cycle of the actuator? How much energy will the actuator consume? What is the performance window of required force? What is the travel distance of the actuator? At what speeds should the actuator operate? What test profiles are required?

Some of the most critical tests required for electromechanical actuators include:

-

Constant Load

-

Dynamic Load

-

Response

-

Accuracy

-

Backlash

-

Frequency Response

-

Inverter Performance

-

Jam Fault Response

-

Positional Accuracy

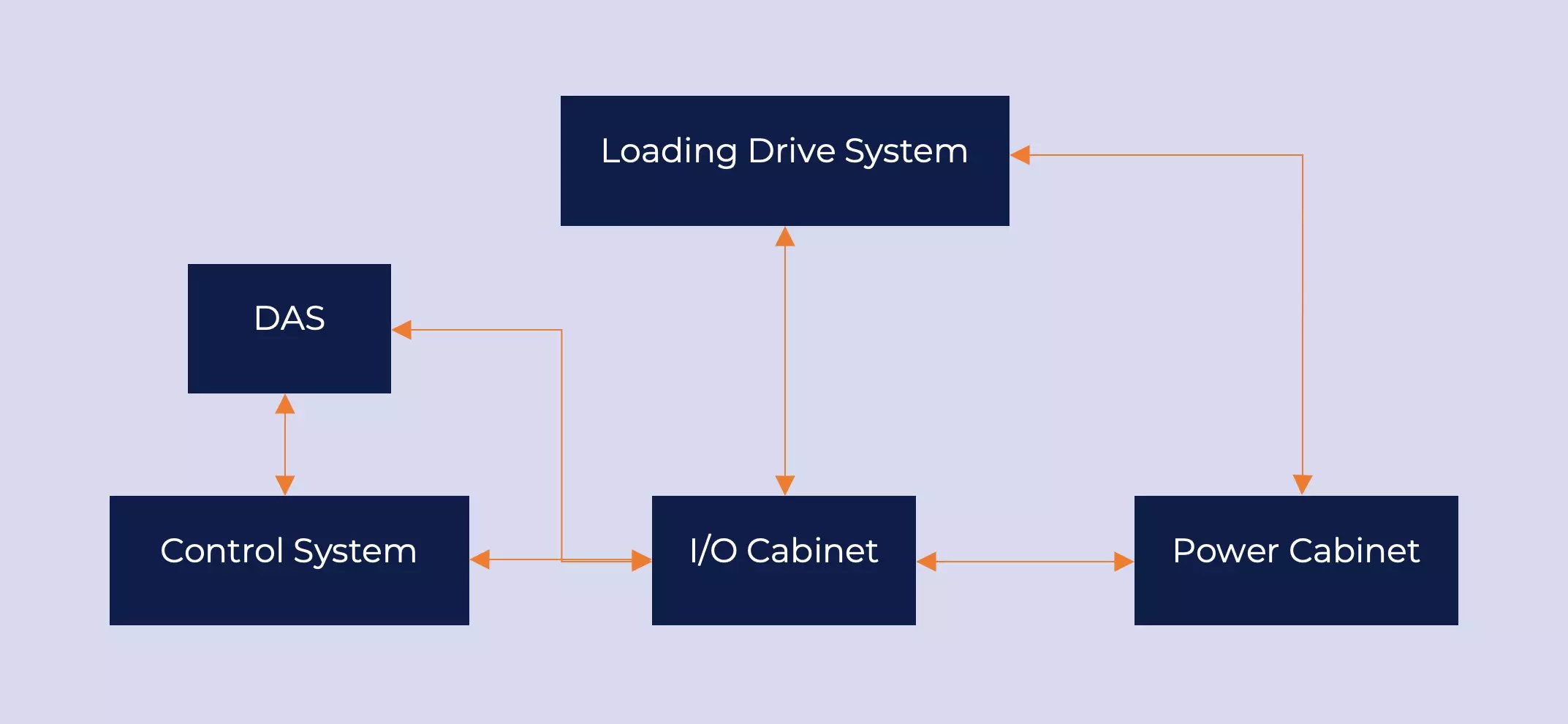

Systems designed for physically testing hydraulic actuators require a supply of hydraulic fluid and associated piping, tubing, and valves. Similarly, pneumatic actuator test systems require an air supply (sometimes an air compressor) and associated ducting. An electromechanical actuator test system is less complex and requires only facility power. Electromechanical actuator test systems consist of a loading drive system, a control system, a data acquisition system (DAS), an input/output (I/O) cabinet, and a power cabinet.

Electromechanical Actuator Physical Test System Block Diagram

In a typical physical testing setup, the control system is a simulation of the electromechanical actuator controller. This system will simulate signals from the controller to execute the test profiles, designed to emulate the various scenarios the actuator will encounter in normal and extreme operating conditions.

Hardware-in-the-Loop Simulation of Electromechanical Actuator Controllers

With Hardware-in-the-Loop (HIL), the development of the controller can be done in parallel with the mechanical elements of an actuator. HIL testing allows you to simulate input/output signals that will be received/sent by the electromechanical actuator controller hardware configuration. A HIL system uses programmed models to emulate the signals that a controller will receive from the mechanical element of an actuator (i.e., the hardware) in real scenarios, such as during actuator loading or when a jam fault occurs. These simulations are critical for observing and determining how the controller will behave in the various situations that the actuator will be operated. In addition, a HIL system can simulate any missing pieces from the system setup (e.g., simulating signals from aircraft avionics, or simulating motor signals when a motor is unavailable). This closed-loop testing provides more accurate data and better test coverage than a software model, which means a better chance of finding any anomalies earlier in the development cycle.

Integrated Testing of Electromechanical Actuators with Their Controllers

Performing physical testing and HIL simulation of electromechanical actuator systems independently presents some challenges. Often, the controller and mechanical components of an actuator are developed by different engineers. Despite their best efforts at collaboration, there can be issues with communication and control that only present themselves after the actuator system is integrated.

Testing the controller and mechanical components of an electromechanical actuator system separately increases your capital expenditure, requiring two separate test systems. This takes up more space in your facility and requires multiple skilled operators. In addition, testing independently adds valuable time during product validation that could prevent you from being the first to market.

At Genuen, we provide an opportunity to integrate your physical and HIL testing on one system. With a single test system, you can reduce your overall development costs. An integrated system allows you to test the controller and mechanical components of your electromechanical actuator system earlier in the product design cycle, improving your time to market. The tester can be operated by one technician, reducing your labor costs. Genuen’s system provides automation with VeriStand, TestStand, and INERTIA, which simplifies test system operation. This software is flexible and adaptable, allowing you to adjust your testing operation without programming experience.

Integrate your Testing with Genuen

When considering test solution providers, look for someone who can partner with you throughout your development cycle. Genuen can provide you with robust performance test systems for validation and verification testing with the flexibility to support your production and acceptance testing needs with qualification test systems.

Learn how to combine HIL with physical testing in our blog post, "How to Combine HIL with Mechanical Systems Rigs to Create Electromechanical Test Rigs."