When preparing safety-critical products for certification, many are surprised to discover verification and validation (V&V) costs can be as expensive as your development costs. However, robust V&V is crucial to avoid issues like incompatible interfaces traced back to inadequate requirements validation. For example, you may be ready to install a new product in a safety-critical system, only to find the interface does not function because requirements were improperly validated upfront.

With today's complex, safety-critical systems, thorough V&V is fraught with potential conflicts of interest when done solely in-house. Validation is the process of confirming that product requirements accurately meet the true needs and use cases of the customer. Verification involves rigorous testing, analysis, and reviewing to confirm a product correctly meets its defined requirements and specifications.

Dependent on the criticality of the system, the aviation industry requires verification by an independent party, according to standards, such as DO-178C. Other mission-critical industries are increasingly recommending independent V&V, including the automotive industry, which has begun adopting the functional safety standard ISO 26262.

While it can be tempting to perform V&V on your software in-house in the interest of reducing costs or expediting your development timeline, self-verification and -validation can be risky and costly. Lives depend on critical technologies working exactly as intended, every time. By collaborating upfront with an experienced V&V firm, you can build quality in from the start and avoid costly rework down the road.

In this blog, we’ll be reviewing the top reasons you should have a V&V partner:

-

Self-verification and -validation have inherent conflicts of interest.

-

Early partnership on V&V can help you avoid missteps later in development.

-

A V&V partner brings an independent perspective.

-

V&V partnership allows you to leverage specialized expertise.

-

Working with a V&V partner improves developmental efficiency.

Built-In Conflicts of Interest

As engineers, we naturally want to trust our own work. It feels more efficient to perform V&V of designs internally since we know them so intimately. However, this intuitively appealing approach inevitably leads to blind spots. Minor oversights, dubious assumptions, and small shortcuts add up over time. Without an independent perspective, these biases accumulate until they can become dangerous defects.

In the real world, undetected defects due to inadequate internal V&V have led to challenges and costly resolutions, sometimes even shutting down the use of the products.

Facing pressure to accelerate V&V, developers may take shortcuts during robustness testing with inadequate approaches. However, just one unanticipated scenario in the field could lead to catastrophic failure in a safety-critical application.

Similarly, engineers tend to mentally fill in gaps in requirements, relying on organizational knowledge. Broad partner expertise across industries can shed light on scenarios you may not have considered. Relying solely on institutional memory is a ticking time bomb—not to mention lost knowledge when experienced engineers retire.

Other times, internal teams become desensitized to alarms or warnings during V&V. The inevitable creeping acceptance of failure leads directly to decreased reliability. Independent V&V provides a fresh perspective to identify these issues.

The Earlier the Better

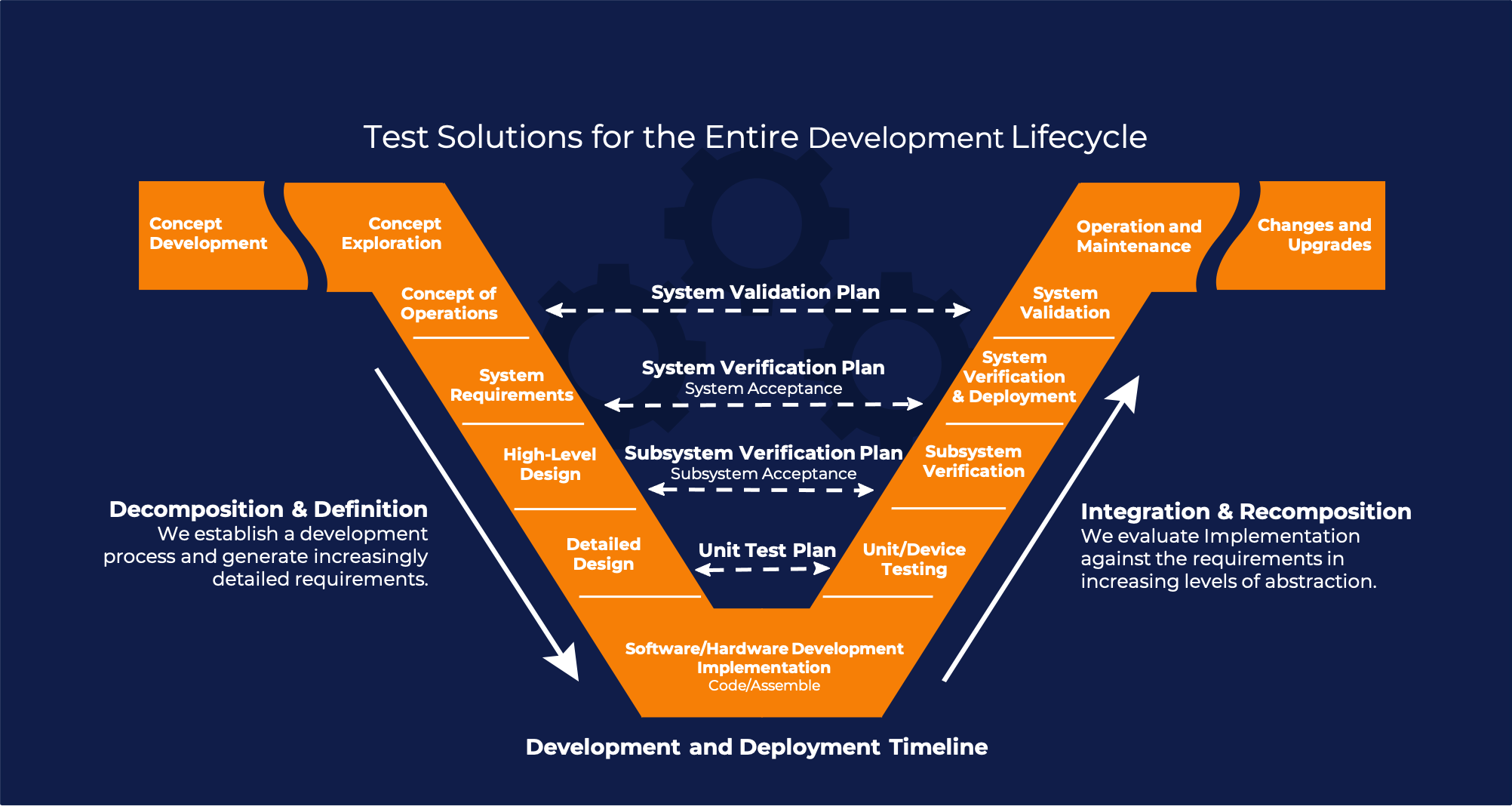

Partnering with a V&V expert early on in your product development cycle provides the greatest benefit, helping you to accelerate your time-to-market and save on potential rework costs later. V&V occurs throughout nearly every phase of the product development lifecycle; however, the optimal time to involve an independent partner is during the decomposition and definition phases of development.

There are multiple opportunities to bring in a partner for V&V throughout the development lifecycle. Early involvement during the decomposition and definition phases can streamline V&V during integration.

During these early stages, V&V experts employ techniques like requirements reviews, simulations, and modeling to validate that high-level product requirements accurately reflect customer needs. By partnering with a V&V firm at this point, critical requirements gaps and product defects can be identified early when changes are relatively easy and cost-effective.

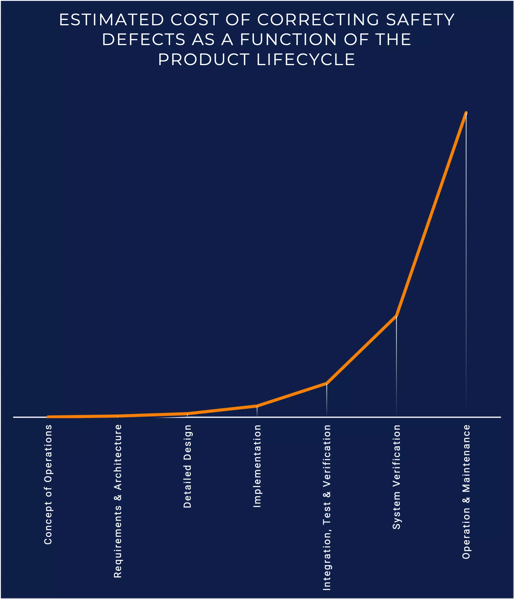

As product development progresses, the cost of making changes and correcting errors rises exponentially.

Continuing through each design phase, an experienced V&V partner can audit your emerging architecture and provide invaluable guidance to optimize the product for eventual verification. They can advise on best practices for instrumentation, diagnostics, and other design-for-test capabilities to build into your product upfront. This expert guidance during design helps avoid significant rework costs down the line. Even minor oversights in system V&V plans can lead to costly failures and rework once deployed if not caught early.

Accelerating time-to-market is another key benefit of early-stage V&V. Rather than waiting until later system verification and validation phases, partnering early allows test planning and preparation to happen in parallel with design and implementation. This parallel workflow results in a faster path to market, while still ensuring rigorous V&V.

A Partner Brings Independence

A critical benefit of bringing in an outside V&V partner is the independence and objectivity they offer. When engineers test their own work, there is an unavoidable confirmation bias that creeps in. As mentioned above, engineers want to demonstrate that their designs meet requirements, so they subconsciously gravitate toward acceptance versus rigorous analysis.

An independent partner avoids this self-validation and -verification bias. They have no vested interest in proving your design successful. This allows fresh objective scrutiny of each requirement, hunting for gaps and inconsistencies without preconceptions. An experienced partner adeptly plays devil’s advocate, considering scenarios and perspectives internal teams may be blind to. The outsider viewpoint leads to insights and catches issues that overburdened internal resources may overlook when verifying or validating their own work. The independence and neutrality of a third-party partner results in a far more rigorous V&V.

Expanded Expertise

Another major advantage of leveraging an external partner is their expansive base of expertise drawn from diverse industries. Seasoned partners bring extensive real-world V&V experience across many industries, from aviation systems to medical devices and beyond. This exposure allows them to identify test scenarios, failure modes, and risks that even the most diligent internal team may overlook. Robust V&V requires thoroughly exercising a product in ways that may exceed the knowledge bounds of a single company.

Partners also bring extensive knowledge of proven V&V methodologies. They understand how to create repeatable, documented processes that will satisfy the toughest certification audits. From requirements tracing to code coverage analytics to environmental stress screening, their toolkit and best practices ensure controlled, comprehensive, and compliant V&V far beyond what an internal team could establish alone. Tapping into this wealth of knowledge helps ensure V&V are as robust, repeatable, and bulletproof as possible.

Improved Efficiency

Finally, teaming with an established V&V partner improves efficiency for product teams. An experienced partner brings far more than just testing manpower. The real value is in varied experience, contributed process rigor, industry best practices, advanced test tools and automation, and other resources. Companies benefit from this turnkey V&V infrastructure without diversion from their core development initiatives. Along with building internal V&V engineering capabilities, companies can leverage their partner’s existing skills, tools, and labs. Engineers can remain focused on design and implementation work rather than becoming bogged down building internal V&V functions.

Partner with Genuen for Your Verification and Validation

In today's unforgiving marketplace, leveraging outside V&V expertise early in your project lifecycle is a major competitive advantage. The modest incremental cost is overshadowed by risk reduction, faster time-to-market, higher quality, and a safer product.

At Genuen, we are unconditionally dedicated to safe, reliable products where technology touches humanity. Catching hidden flaws and risks comes naturally to us thanks to our fresh perspective, while our expansive technical breadth guarantees no test case is overlooked. Our long experience allows us to evaluate completeness, clarity, and testability from the ground up to help you ensure product safety.

Designing a new product? Check out our training “The Fundamentals of Verification and Validation in Software Development for Airborne Software”.