We all have them: the ones that have been around so long that we have named them “Old Blue,” “The Gray Ghost,” “Legacy-One,” or even “That Old Piece of ####.“ Yes, it’s that old test bench that has been around forever. Tucked away in a back room and kept out of sight, but yet we hold onto them for some reason. We keep them because we may use them on “that one valve,” maybe they seem too valuable to scrap, or perhaps just for sentimental reasons. Multiple valves that leak or have been disconnected, broken handles, gauges which haven’t been calibrated for years, broken or missing components, visual flow meters that have clouded over and are no longer readable, and manually recorded pressures or flows that are left to interpretation are all reasons to consider an upgrade of your current stand.

If you are considering an increase in your current testing capacity, providing your lab with faster automated testing, or just upgrading for higher accuracy testing, then perhaps now is the time to utilize that old friend and schedule your Test Stand Makeover.

Figure 1: "The Gray Ghost" may have over 25 hand adjustments, a few missing gauges, and a few leaks here and there, but she’s like family.

The Test Stand Makeover

System makeovers can consist of many different aspects including:

-

Replacement of pressure and temperature gauges with digital meters

-

Conversion from visual flow meters to transducers

-

Upgrading the hydraulic power unit with a more energy efficient unit

-

Conversion from manually operated valving to automated solenoid or proportionally controlled valving

-

The manifolding of the control valving into one single package to reduce the number of potential leak points on the stand

-

Reducing the associated noise or heat introduced into the test lab

-

Automating the stand for single or multiple UUT testing

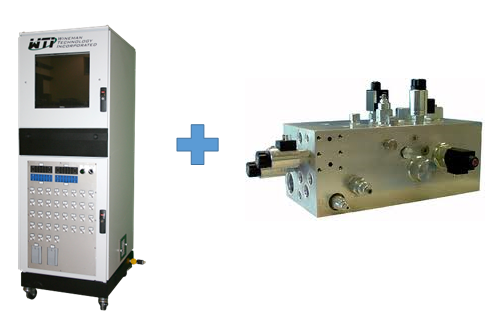

Figure 2: The combination of a new control system and custom manifold(s) can provide the Operational Makeover your system now requires to increase your testing capabilities.

Automated Controls

Many existing applications require multiple connections and disconnections of fluid conductors for each step of the test sequence. In the past, this has been required due to specific test stand circuit limitations which need to be interfaced to the UUT. Not only does this process result in lost testing time, but it can cause potential interconnection errors, leaks, and test failures.

By upgrading your system, it is possible to eliminate the step-by-step, connecting and disconnecting of the UUT during each step of the test, so that the technician may only have to connect the UUT once for the entire test. The system then automatically selects valving, required for each individual test, throughout the efficient stepped sequence. The control system can also pause and prompt the technician if a manual test or inspection is required within the test sequence. Plus, the control system can automatically monitor and collect all data in a custom format that includes graphs, comparison data, and trending. Test logging for serial number, manufacturing or test date, and bar coded information can also be available for storage or manipulation at a later date.

Now not only can a system be configured for a single automated test, but it can also be engineered flexible enough to allow for multiple test samples to be combined through the use of the same custom manifolds, automated control systems, and valve utilizations.

A Makeover Analysis

In these days of runaway steel prices, test stand upgrades can be a tremendous cost savings over the purchasing of new stands. A stand upgrade can not only allow for the utilization of your existing frames and custom fixturing, but also saves installation costs by providing a form, fit, and function replacement into your existing stand’s location.

Genuen has years of experience in the upgrading and automation of not only existing test stands, but also entire test cells. We offer the market leading expertise required for the addition of data acquisition and control systems to your systems. Systems can be totally upgraded, onsite or offsite, or be upgraded in several “add-on” phases that spread the cost for a total system upgrade over several budget cycles. Please contact us for a system analysis today and see if it's time to rename your test stand to “The New Blue,” “The Gray Beauty,” or even “Test Stand-One.”

For More Information